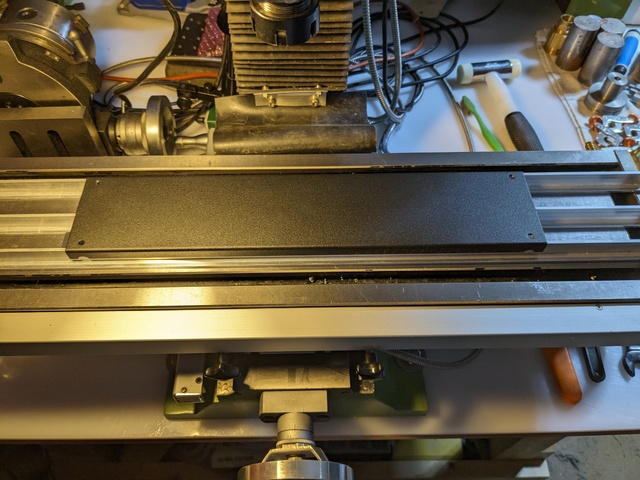

This is a 2U (i.e. 2×1.75") high rear panel for a 19" rack case.

These parallels and T-section aluminium just happen to be a nearly exact fit.

Once again, a project that's very slightly too big for my machine.

Indicate it parallel with the table travel.

This is a through-coolant annular cutter holder. A very nicely built piece of kit from Germany, which I very crudely modified with an angle grinder to remove the tang and make fit my spindle's taper.

I added two more clamps, which overhang the table even more.

This cutter makes nice holes, and it makes them really quickly. Which is good, as there are thirty two on the panel.

The angle between the bar and the mill head doesn't look like much, but it creates enough side load to make the cutter holder fall out of the spindle if I'm not careful. I rotated the bar to improve this, but it just slipped back to the original position when I started the spindle. More work needed.

The usual bird's nest.

I first tried the through-coolant with the supply on all the time. I guess it would be nice if you were cutting through structural steel on a building site but it's a bit too enthusiastic for here.

Using the coolant supply in short pulses is much cleaner.

All the (big, circular) holes complete.

The total bird's nest. There is also a nice collection of aluminium disks under the panel.

Cleaned off and ready for the next operation.