The mating parts have a rectangular alignment feature, but I'm cheating with a drill since it's far quicker and won't be seen once assembled.

A part fitted (on the wrong side, but it's just a check).

All done.

This is another cheat. These slots should be trapezoids with rounded corners, but the short sides are at such a slight angle that a rectangle works (and looks) fine.

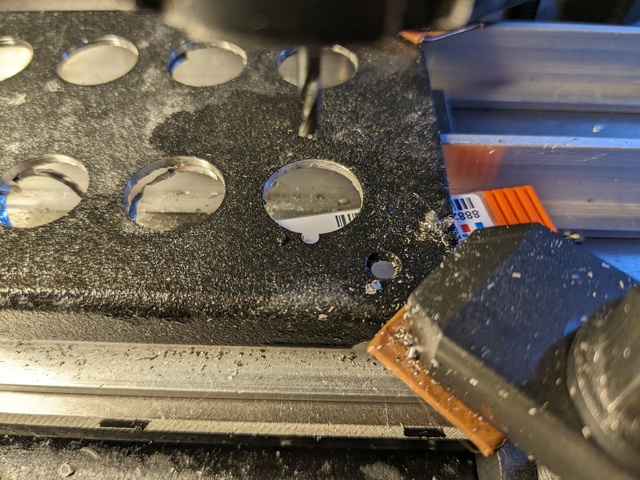

Each slot needs two holes for fixing screws.

All these features need labelled, so I'm making a very shallow (0.2mm) pocket to give the label a smooth surface to stick to. It also keeps it below the nut that secures the circular parts.

My corner-only clamping system made the panel bow slightly, so the label pocket is deeper in the centre than at the ends. I will have to improve this before production.

Lots of nasty burrs on the bottom, but the large holes are easy to tidy up.

A thorough visual inspection against the design.

Just needs the labels now.

Parts fitted to a cleaned up panel.